The Current Challenge

India has transitioned from a low-cost, cheap labor-sourcing location to a more mature & quality-sensitive environment. However, it continues to be a price-sensitive market. Given that overall operational costs have increased manifold, businesses are under severe pressure to maintain margins. To sustain growth and profitability we must look inwards to improve the operational efficiencies, productivity and reduce wastage.

Information Systems – The Next Wave in Supply Chain

The competitive edge Information Systems provide has changed over time. A typical view of competitive advantage in the past and now is depicted below:

We are witnessing the emergence of a new wave of solutions that look at finer aspects of the supply chain. This includes:

- Extended Enterprise Solutions

- Warehouse Management

- Automated Storage & Retrieval System

- Business Intelligence

- Supply Chain Design & Route Planning Solutions

While such solutions have been available in the past, enterprises have only now started to recognize the benefits of these systems. Broad-based adoption is on the rise. Let us look at these briefly.

Extended enterprise solutions, as the name suggests, look beyond enterprises and their ERPs. Suppliers, Customers, Cross Dock Locations, 3rd Party Providers, etc., are numerous links in a supply chain. “A chain is as strong as the weakest link” is an oft-heard quote and it holds all the more in the context of Supply Chains also. Extended Enterprise Solutions address this crucial gap. Strengthening the partner communication and network ensures greater predictability and a direct reduction in the cost of managing a supply chain.

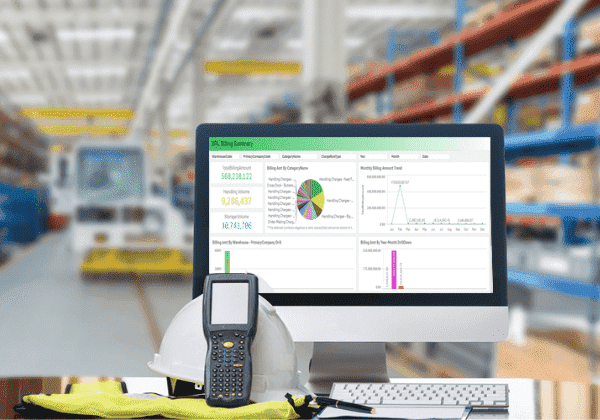

3PL Warehouses, Food, and Agriculture Commodity Warehouses, and much of the Sales and Distribution warehouses continue to run on manual spread-sheet-based informal systems. This results in tremendous wastage in terms of labor, space utilization, and damaged & missing SKUs. Management Controls are to that extent weakened. Warehouse Management Systems shall therefore play a key role in strengthening the overall Supply Chain.

Space rentals and costs shall continue to rise steeply and this creates a direct pressure to utilize current space most effectively. Automated Storage and Retrieval Systems (AS/RS) help in setting up high-rise racking infrastructure and thereby ensure much greater utilization of effective space. Warehouse throughput can be increased manifold with the help of robotic stackers, conveyors, and RFID/Barcode-based interfaces. A key success factor in all AS/RS projects is an effective Warehouse Management System which must optimally manage incoming inventory, location suggestions, and outgoing stock. AS/RS systems are expensive to implement and the adoption of poor warehousing principles can reduce the ROI and extend payback periods unreasonably.

As the size of enterprises increases, decision-making becomes all the more complex. Even seemingly common-sense decisions must be backed by adequate data. Business intelligence solutions form the bedrock of informed decision-making within an enterprise. “In memory” Business Intelligence solutions in particular are well placed to provide solutions to this market segment.

Similarly, supply chain design and route planning, much-neglected aspects of the supply chain, become important in the face of rising fuel prices. The availability of digital map data for most of the Indian cities and countryside makes it easier to implement such solutions. While route planning software evaluates and suggests the best route for a delivery run, supply chain design software help in placing the key distribution hubs at the right locations effectively.

All the above solutions leverage some form of web infrastructure. Internet and web-based solutions become very important in linking various parts of the supply chain into a meaningful whole. SaaS solutions in particular lower the cost of ownership through better risk management and improved agility in dynamic business situations. Extended enterprise and partner integration requires large-scale adoption of global standards such as Rosetta Net or ebXML. All these changing dynamics provide for an extremely exciting period ahead during which current enterprise applications will evolve into the next generation SCM systems.

How does the Industry 4.0 revolution change supply chain? Read more here.