Modern warehouses are becoming increasingly dependent on integrated software systems to manage inventory, fulfill orders and optimize workflows. According to Grand View Research, global warehouse automation is projected to reach USD 59.52 billion by 2030, growing at a CAGR of 18.7%. This is a clear indicator of how digital solutions like WMS and WES are transforming warehouse operations.

A Warehouse Management System (WMS) serves as the central data hub of a facility. It tracks SKUs, bin locations and stock levels while integrating with ERP and other enterprise systems to coordinate key processes such as receiving, put-away, picking, and shipping. In contrast, a Warehouse Execution System (WES) acts as the operational brain on the warehouse floor. It helps in sequencing tasks and directing workers, conveyors and robots in real time. In this whitepaper, we will explore how WMS and WES work to create smarter, real-time warehouse operations.

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is a software solution designed to oversee and control all major warehouse operations. It provides a real-time view of inventory and orders across the entire facility.

By tracking every SKU, bin location and stock quantity, the WMS ensures that warehouse activities are executed with accuracy and efficiency. Typically, the WMS organizes work into batches or “waves,” assigning specific tasks to operators, conveyors, or other automated systems. It also integrates seamlessly with enterprise platforms such as ERP, transportation management and finance systems to synchronize inventory movements and reporting.

What is a Warehouse Execution System (WES)?

A Warehouse Execution System (WES) is a software designed to manage and optimize real-time warehouse floor operations. Unlike a WMS, which focuses on planning and coordination, the WES continuously executes and adapts workflows on the go.

A WES receives task lists from the WMS and dynamically assigns jobs to workers, conveyors and robots based on current conditions in the warehouse. For example, if a picker falls behind or a conveyor experiences downtime, a robust WES can instantly rebalance workloads. It can reroute robots or reallocate tasks to maintain high throughput.

Modern WES solutions leverage AI-driven algorithms for waveless order processing and dynamic job sequencing, enabling just-in-time fulfillment instead of rigid, pre-scheduled task waves.

The WES functions as the operational brain of the warehouse floor. It helps in orchestrating forklifts, sorters, AMRs (autonomous mobile robots) and staff in real time. This continuous adaptation ensures smoother workflows, reduced idle time and consistently higher performance, even under fluctuating demand or unexpected disruptions.

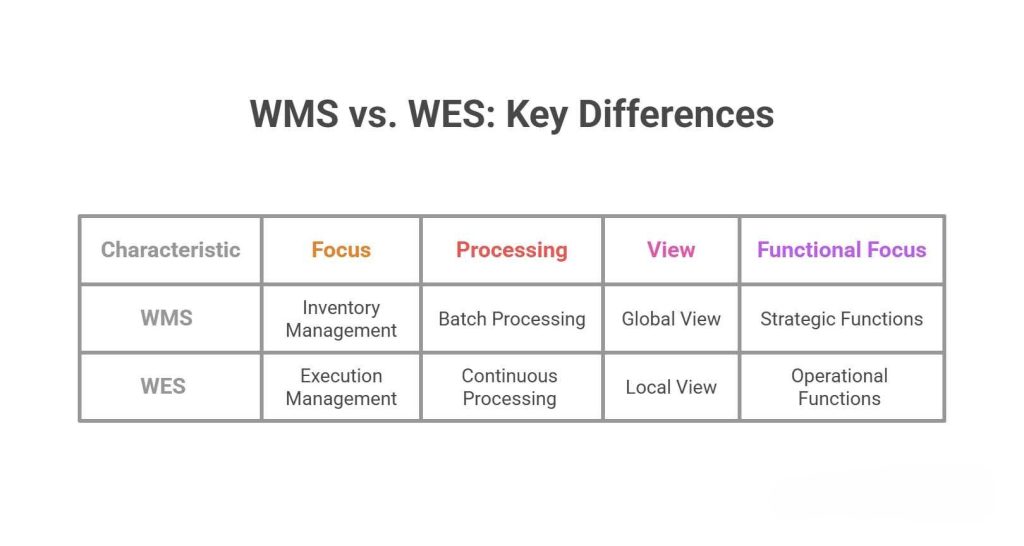

Key Differences Between WMS vs WES

While both systems are essential to modern warehouse operations, they serve distinct yet complementary roles. Key distinctions include:

Inventory vs. Execution

A WMS manages inventory data and high-level order fulfillment. It helps in determining what to ship, when to replenish and where to store.

On the other hand, a WES focuses on execution. It focuses on deciding how to ship, who should perform each task, and in what sequence.

Batch vs. Continuous Processing

Traditional WMS workflows operate in planned waves or batches, releasing groups of orders at scheduled intervals. The WES, however, enables waveless continuous picking, where orders are released and executed the moment they enter the system. This real-time flexibility reduces idle time between waves and helps warehouses meet increasingly tight SLAs.

Global vs. Local View

A WMS provides a global perspective for managers and enterprise systems. It helps oversee total stock levels, inbound and outbound flows and overall warehouse capacity.

Meanwhile, a WES delivers a local, ground-level view, monitoring every aisle, station and worker in real time. It dynamically adapts routes and task assignments to prevent congestion and maintain smooth operations.

Functional Focus

The WMS handles strategic functions such as order allocation, inventory control, reporting, and labor planning. The WES, on the other hand, manages operational functions like conveyor control, robotic coordination, voice- or light-directed picking and dynamic putaway. Together, they bridge the gap between planning and execution, creating a seamless, high-performing warehouse ecosystem.

Real-Time Integration Between WMS and WES

In a modern warehouse ecosystem, the WMS and WES work hand in hand through continuous data exchange enabled by APIs or middleware. This real-time integration ensures seamless coordination between high-level planning and on-the-floor execution.

In practice, the WMS releases tasks such as orders, transfers, or replenishments into the WES. The WES then translates these instructions into actionable commands for devices on the warehouse floor. It helps in directing AMRs (autonomous mobile robots) to retrieve pallets, conveyors to move totes, or pickers to fulfill specific orders.

As each task is completed, the WES immediately sends status updates back to the WMS. This live feedback loop keeps inventory counts, order statuses and task priorities perfectly synchronized across systems. For example, when a pick is confirmed by the WES, the WMS instantly updates stock levels to prevent double-picks or stockouts.

Modern WES platforms further simplify this process with built-in APIs that enable “plug-and-play” integration with robots, conveyors, put-walls and other automation hardware. It helps in minimizing setup time and ensuring reliable real-time communication.

In essence, this smart integration bridges the gap between WMS (planning and data management) and WES (execution and control), allowing every barcode scan, sensor signal, or task update to flow instantly through the system for unmatched accuracy and efficiency.

The Integration Process

Real-time integration between the WMS and WES follows a tightly coordinated cycle that keeps data and operations in perfect sync. Here’s how it works:

- Task Generation: The process begins when the WMS receives an order or shipping request. It allocates the required inventory and prepares the task for execution.

- Task Dispatch: The WMS then pushes this task to the WES through an API connection. The WES organizes and sequences the task queue based on real-time priorities such as order deadlines or equipment availability.

- Execution: The WES assigns specific jobs to warehouse operators or robots. Each assigned worker or AMR (autonomous mobile robot) completes the task, for instance, picking an item and confirming completion via a barcode scan.

- Real-Time Update: Once the task is completed, the WES instantly sends the results back to the WMS (and integrated ERP systems). This ensures that inventory counts, order statuses, and task progress are updated in real time.

- Continuous Feedback: If any issues arise, such as equipment downtime or a stockout, the WES detects the exception and dynamically reassigns or reprioritizes tasks to keep operations moving smoothly.

This continuous loop of task sharing, execution tracking, and live feedback forms the backbone of the process. It enables a unified, responsive flow of information across the warehouse.

Benefits of Real-Time Smart Integration by WMS and WES

Integrating the WMS and WES in real time delivers tangible, measurable advantages across warehouse operations.

Faster Fulfillment

Continuous task scheduling and adaptive routing powered by WES dramatically increases throughput. By minimizing idle time, eliminating bottlenecks and dynamically reallocating work, warehouses can achieve significantly faster pick-and-pack speeds. This agility allows operations to meet tight SLAs and process more orders per shift without additional labor.

Higher Accuracy

Instant inventory synchronization and automated error checking lead to greater accuracy across all processes. Since the WES confirms each pick and immediately updates the WMS, the risk of overselling or shipping incorrect items drops sharply. Real-time validation also reduces stockouts and minimizes manual reconciliation work, ensuring smoother and more reliable order fulfillment.

Flexibility and Scalability

Real-time integration enables systems to adapt to changing operational demands. During peak periods, such as holiday seasons or product launches, the WMS and WES automatically rebalance labor and machine workloads to maintain performance.

Modern WES platforms also support easy scalability through API-based integrations, allowing new automation technologies like RFID, conveyors, or AMRs to be added seamlessly without major software overhauls. This flexibility ensures that warehouses can expand or evolve without costly downtime.

Data-Driven Insights

Together, the WMS and WES capture detailed operational data that drives continuous improvement. Every task, scan and movement is logged, producing analytics on throughput, equipment utilization and labor efficiency. With intuitive dashboards displaying key metrics, such as orders per hour, picker accuracy, or robot idle time, managers gain clear visibility into performance and can make informed, data-backed decisions.

By combining the strategic inventory control of a WMS with the real-time execution intelligence of a WES, warehouses unlock greater responsiveness, accuracy and efficiency. The result is higher ROI, as facilities can fulfill more orders, reduce errors, and scale operations, all within the same space and workforce.

How PALMS™ Smart WMS Can Help You

Warehouse Management Systems (WMS) and Warehouse Execution Systems (WES) serve distinct, yet complementary roles and their real-time integration is essential for achieving high-performance logistics. By linking “what” needs to be done with “how” it is executed, smart WMS and WES integration empowers logistics leaders to streamline workflows, reduce errors, and gain a clear competitive advantage in today’s fast-paced supply chain environment.

Our PALMS™ Smart WMS is designed to streamline warehouse operations by combining powerful inventory management with real-time execution insights. With our technology, you can track every SKU, optimize order fulfillment and gain instant visibility into your warehouse performance. Its seamless integration with WES and other automation technologies ensures faster picking, higher accuracy and adaptable workflows, all while reducing errors and boosting efficiency.

Ready to take your warehouse operations to the next level? Get a free consultation today to discover how PALMS™ Smart WMS can transform your fulfillment process, boost efficiency and drive measurable results.