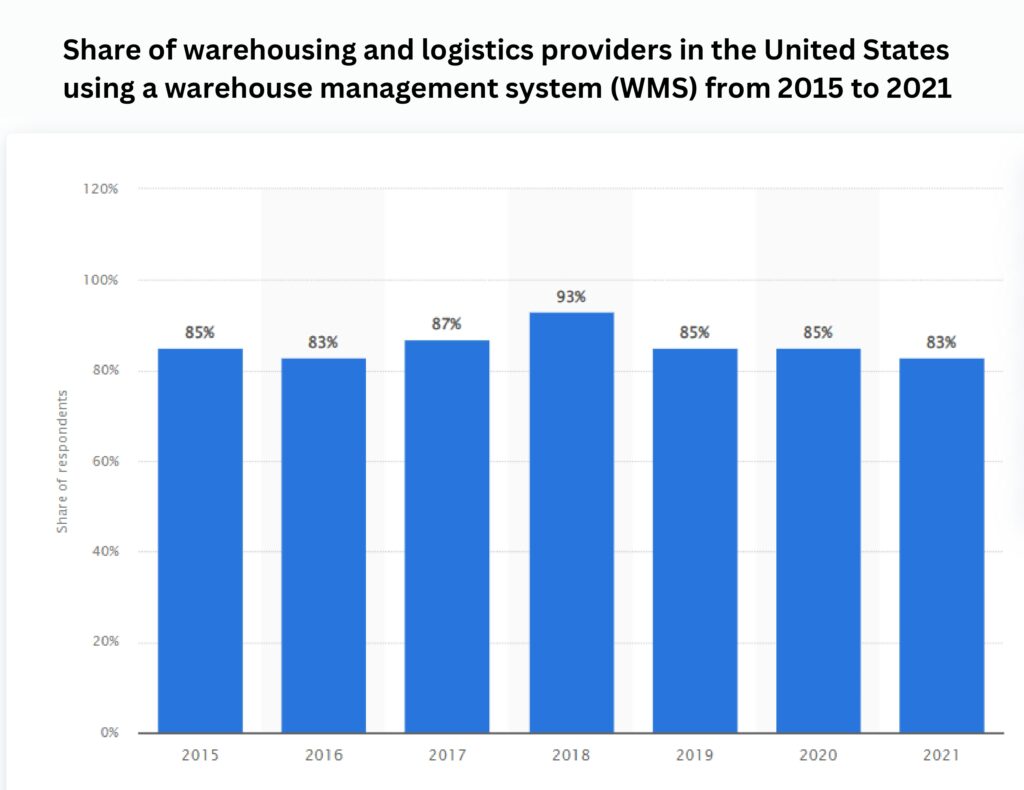

Since Amazon has become ubiquitous around the world, customer expectations for order fulfillment efficiency have skyrocketed. Now more than ever, in the current marketplace, efficient warehouse management software can set you apart. The market for warehouse management systems is anticipated to rise US$7.90 billion by 2027, at a CAGR of 9.2%. 83% of warehousing and logistics providers in 2021 are using a Warehouse Management System.

The numbers make it clear. If you want to compete and stay relevant in the logistics industry, a Warehouse Management System (WMS) is indispensable.

But what is a “Warehouse Management System (WMS)” and what can it do for you? This article will take a deep dive into WMS and serve as your comprehensive guide for navigating the world of warehouse management systems.

To summarize:

WMS Meaning: A warehouse management system is a software that can help manage all the activities constituting warehouse operations and also help improve on them.

Benefits of a Warehouse Management System :

A Warehouse Management System offers a comprehensive suite of benefits that extend across various aspects of warehouse operations. From optimizing inventory management to enhancing order fulfillment, reducing errors, and providing real-time visibility, a warehouse management software (WMS) has the potential to revolutionize how businesses manage their supply chain and logistics. With increased accuracy, efficiency, and the ability to make informed decisions, companies can position themselves for success while delivering exceptional customer experiences.

Optimized Inventory Management:

A WMS enables accurate real-time tracking of all inventory information. The risk of stockouts and overstocking is greatly reduced, allowing businesses to maintain optimal inventory levels. With a clear view of stock availability, companies can fulfill orders more efficiently and reduce holding costs.

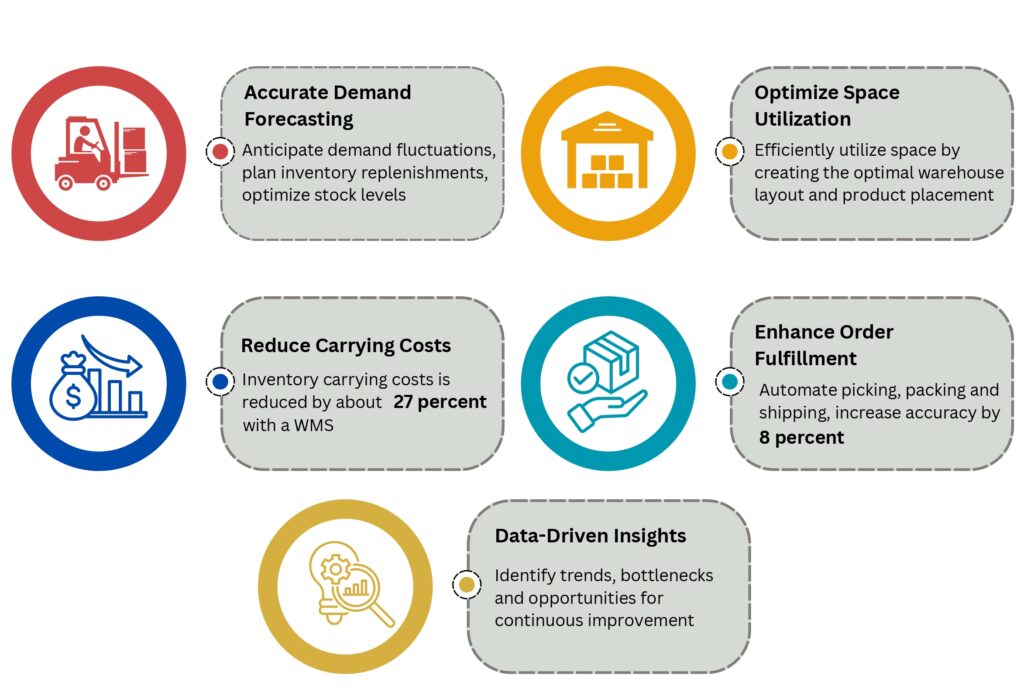

Enhanced Order Fulfillment:

A warehouse management software (WMS) streamlines order processing by automating picking, packing, and shipping. Eliminating the possibility of manual errors means that order fulfillment is faster and more accurate, and customer satisfaction is improved.Also, with real-time visibility into order statuses, businesses can provide customers with accurate delivery estimates.

Improved Accuracy and Reduced Errors:

The warehouse management software (WMS) also offers the capabilities of automating data capture and entry. Barcode and RFID scanning ensure accurate inventory counts and prevent shipping mistakes, ultimately saving time and money.

Optimized Space Utilization:

The warehouse management software (WMS) provides insights into warehouse layout and product placement. This data helps optimize storage space, enabling businesses to maximize their warehouse’s capacity. Efficient space utilization reduces the need for additional storage facilities, saving costs in the long run.

Labor Productivity and Efficiency:

Automated processes within a warehouse management software (WMS) reduce the need for manual labor. Warehouse staff can focus on value-added tasks instead of time-consuming manual tracking. This improves labor productivity, reduces the chance of human errors, and enhances overall efficiency.

Accurate Demand Forecasting:

By analyzing historical data and current trends, a warehouse management software (WMS) can aid in accurate demand forecasting. This enables businesses to anticipate demand fluctuations, plan inventory replenishments, and optimize stock levels to meet customer needs while minimizing excess inventory costs.

Effective Returns Management:

Handling product returns efficiently is essential for customer satisfaction. A warehouse management software (WMS) can facilitate the returns process by providing visibility into returned items, automating restocking procedures, and ensuring that returned products are processed correctly.

Regulatory Compliance and Traceability:

Certain industries, such as pharmaceuticals and food, require strict adherence to regulatory guidelines. A warehouse management software (WMS) can help maintain compliance by tracking batch numbers, expiration dates, and other critical information. This enhances product traceability and minimizes the risk of non-compliance penalties.

Better Supplier Collaboration:

Warehouse management software (WMS) often integrate with suppliers’ systems, enabling seamless communication. This helps in supplier collaboration for timely replenishment, order updates, and efficient inbound logistics. Improved communication leads to a more responsive and agile supply chain.

Data-Driven Insights:

Warehouse management software (WMS) generates a wealth of data related to warehouse operations. By analyzing this data, businesses can identify bottlenecks, trends, and opportunities for continuous improvement. Data-driven insights empower strategic decision-making and operational enhancements.

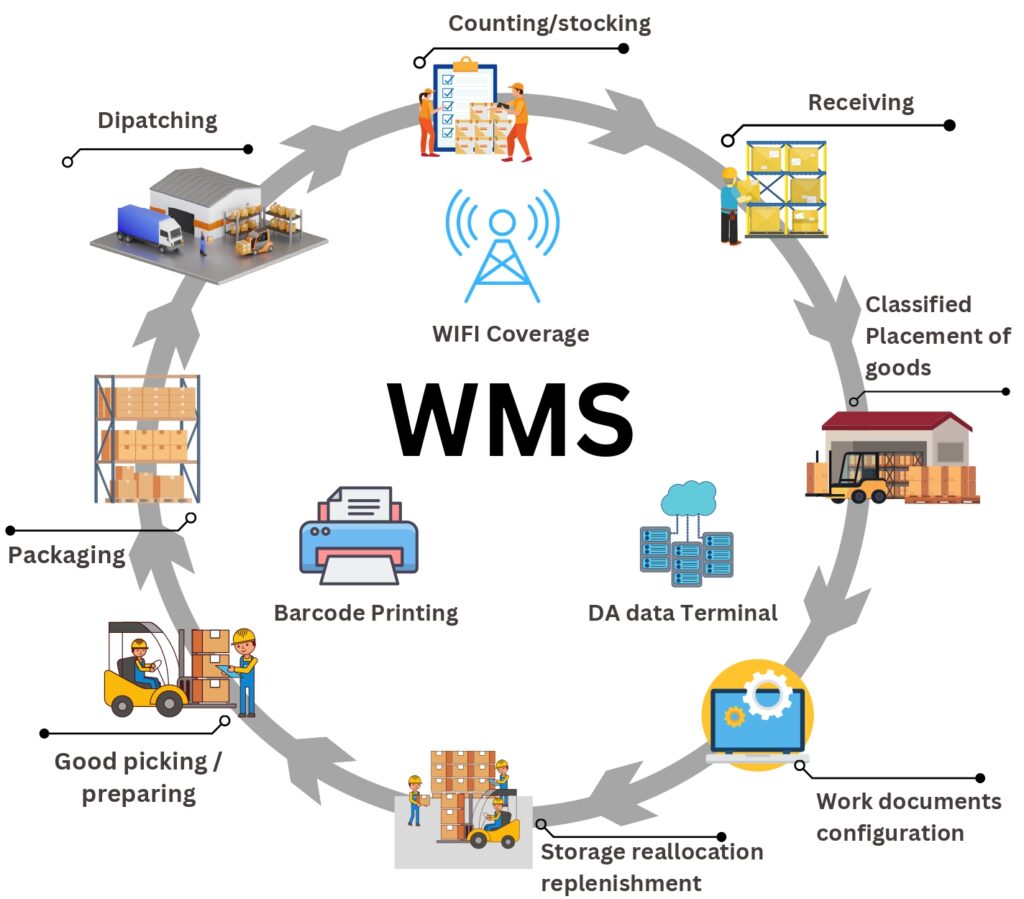

Capabilities of a Warehouse Management Software (WMS)

The functioning of the warehouse consists of activities that create a ripple effect across the supply chain, and determine the overall flow and efficiency in operations. A good warehouse management software (WMS) can make improvements in each of these activities, from inbound workflows to systematized, optimal storage and swift outbound flows. A WMS typically supports the following activities:

Inventory Management

Inventory management in recent years has been revolutionized by the use of automatic identification and data capture (AIDC) technology like radio frequency identification (RFID) and barcodes. The warehouse management software (WMS) always provides real-time insight into the inventory levels and locations. Many modern warehouse management systems also offer demand forecasting and cycle counting capabilities, so that warehouses can adjust stock levels accordingly. This can lead to greater accuracy in order rates.

Warehouse Layout Design

The warehouse management software (WMS) makes recommendations on bin slotting and similar considerations in order to allow for maximum space utilization, while factoring in seasonal variations in the inventory. The warehouse design has a direct impact on optimal allocation of inventory that enables smooth workflow. Organizations can set the picking logic and customize workflows using the warehouse management system.

Order Picking, Packing and Fulfillment

According to a research paper from the University of Nis, typically 55% of the total cost of warehousing is related to order picking. The warehouse management system can guide decision makers toward the path of least time and expense for storing and retrieving products.

This could mean utilizing technologies like pick-to-light, pick-to-voice and choosing the best suited approaches – wave picking, zone picking, batch picking, cross docking, “put” to order, put-wall systems. Features like lot zoning and task interleaving help perform picking and packing tasks as efficiently as possible.

Shipping

Most warehouse management systems are able to integrate with enterprise resource planning (ERP) systems, transportation management systems (TMS), or logistics software. As a result of this, the fulfillment process becomes simplified allowing the WMS system to generate packing lists, shipment invoices, bills of lading, and automatic shipment notifications. With live order status updates, the package can be monitored until it reaches its destination.

Labor Management

The WMS records a number of statistics on labor resources including response times, labor costs, productivity gaps, warehouse workers, trends to plan and so on – allowing companies to react accordingly. The task interleaving features helps minimize the travel time of each worker, planning and scheduling based on priority or proximity.

Yard and Dock Management

Yard and dock management features can guide truck drivers to the right loading docks as quickly as possible. The WMS system is also built for a variety of operational scenarios, like cross docking. In cross docking, the goods arriving into the warehouse are immediately placed into outgoing shipments.

For cross docking scenarios, the warehouse management system can configure routes, validation of material and handle exceptional scenarios, and other inbound and outbound logistics scenarios.

Warehouse Metrics Reporting and Analytics

The analytics and reporting functions of warehouse management systems are crucial to the operation of an orderly, optimized warehouse. A data-driven approach can reveal the areas of improvement in the warehouse.

Since the WMS automatically collects data, it eliminates manual data entry errors and drastically speeds up the process. The analytics typically track KPIs like distribution costs, order cycle time, inventory accuracy, on-time shipping, order fill rate and so on. The warehouse management software (WMS) can also create visual reports for communicating the information to stakeholders in an easier manner.

Types of Warehouse Management Systems

There are four types of warehouse management systems: standalone WMS, cloud-based WMS, supply chain execution modules, and integrated ERP systems.

Type | Description |

Standalone WMS | These solutions are commonly set up within a company’s own facilities, utilizing their hardware. They often allow for more extensive customization, even though this can be expensive, and provide the organization with greater control over their data and software. Once the company has acquired the system, it becomes their permanent asset. However, the organization bears the responsibility of managing updates, upkeep, and associated expenses. |

Cloud-based WMS | Cloud-hosted WMS solutions can be delivered in a software-as-a-service (SaaS) format, granting enhanced adaptability. Continuous updates ensure that warehouse management through cloud-based platforms accelerates the pace of innovation. Furthermore, the responsibility for system maintenance and updates is shouldered by a third party. Additionally, cloud-based warehouse management systems can be seamlessly incorporated with other software solutions. |

Supply Chain Execution Modules | The scope of supply chain management software is extensive, encompassing tasks ranging from overseeing vendor connections to handling business procedures and evaluating risks. Its primary aim is the automation of inventory control, material procurement, and product life cycles. Opting for such a warehouse management system means investing in one that offers warehousing functionalities as well. |

Integrated ERP Systems | ERPs represent robust software solutions that amalgamate functionalities from various other systems. They provide the majority of essential applications for optimizing 3PL operations, spanning supply chain scheduling, sourcing, financial management, client rapport, HR, and more. While integrated ERP systems do include specific warehouse capabilities, warehousing is not their primary focus. |

You can check out in detail about how on-premises deployment differs from cloud-based WMS here.

FAQs

What is a WMS system?

A WMS system streamlines all aspects of warehouse operations including shipping, picking and packing, storage and receiving. It offers real-time visibility on inventory and data analytics that deliver insights to improve warehouse throughput and operational efficiency, while reducing costs and wastage. A WMS system can also be integrated with other software solutions and automation tools.

What is the purpose of a Warehouse Management System?

The Warehouse Management System (WMS) serves the purpose of being the singular platform for handling multiple warehouse locations and all aspects of warehouse management like receiving, putaway, location suggestion, inventory tracking, shipping and billing. It ensures that operations flow in the most efficient and cost-effective manner.

What are the components of a Warehouse Management System?

Warehouse Management Systems contain several modules to handle the various functionalities: the inventory management module, the receiving module, the order fulfillment module, and the shipping module.

How to choose a Warehouse Management System?

Based on the industry, there are some functionalities specifically suited to each business and warehouse. Once your business makes a decision on what features are most important and what the budget is, you can speak with the provider to get further customizations that will help your warehouse.

What are the types of Warehouse Management Systems?

There are four types of warehouse management systems: standalone WMS, cloud-based WMS, supply chain execution modules, and integrated ERP systems. They are classified based on their deployment methods and main functionalities.

Technoforte Software Private Limited is an ISO 9001:2015 & ISO 27001:2013 certified company engaged in providing high end enterprise solution in the field of Information Technology.

Through Technoforte’s suite of products, the company specializes in helping large and medium sized industries in implementing Business Intelligence solutions, Warehouse Management System, Service, and Warranty Management System and Mobile based Enterprise Level Solutions.

COPYRIGHT © 2024 TECHNOFORTE SOFTWARE PVT. LTD. ALL RIGHTS RESERVED.