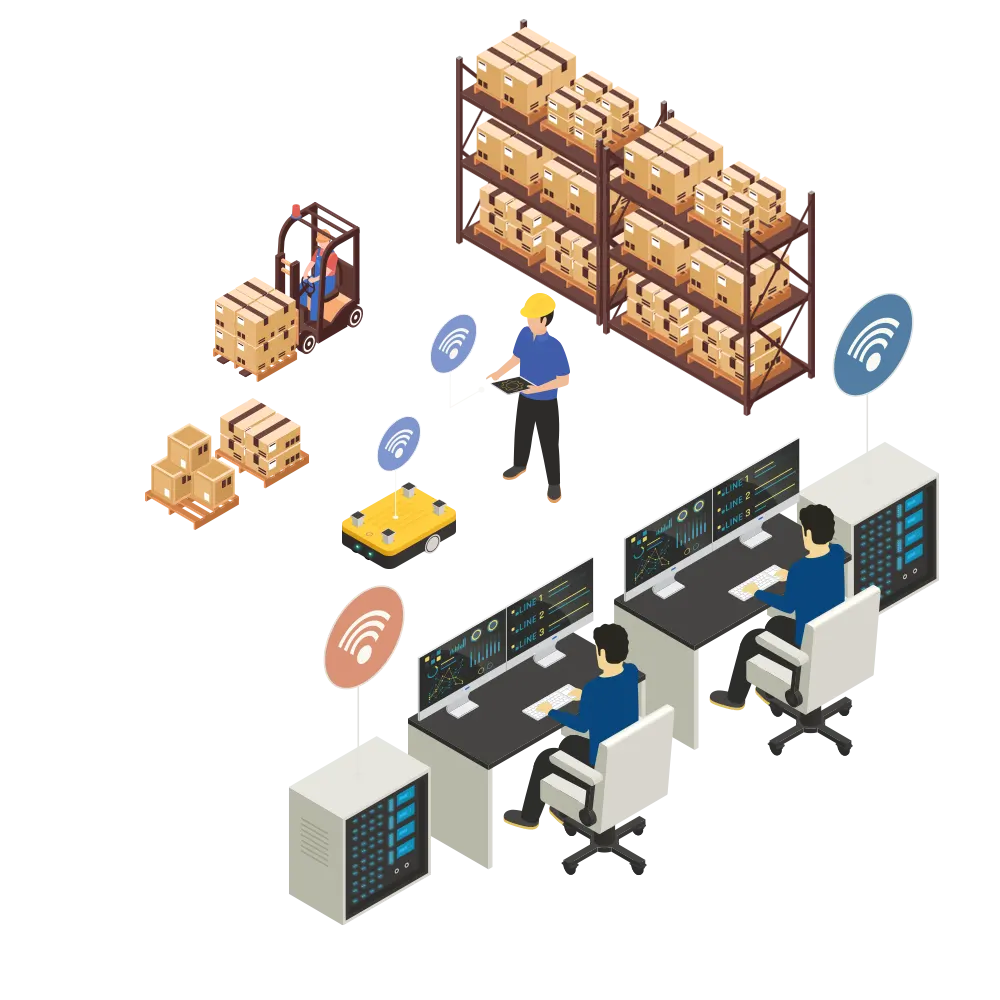

A warehouse control system (WCS) typically acts as a bridge between the WMS Software and Automated Storage and Retrieval Systems (AS/RS).

This allows the WMS Software to provide additional functionalities to the warehouse. The WCS translates the instructions received from the WMS into machine readable language to carry out operations like put away, picking, internal transfers etc.

PALMS™ WCS performs the following functions:

A WMS Software is a broader solution that manages aspects like inbound and outbound operations, ERP integration, and labor management. On the other hand, a warehouse control system is a real-time control solution that manages specific tasks; primarily the storage and retrieval of material within the warehouse.

Some of the functions are elaborated in the table below:

WMS | WCS |

Order Management Integration | Pack Sorter Management |

ERP Integration | Machine Control Integration |

Advanced Receiving | Automated Pick Management |

Management Reporting | In-line Weight and Motion |

Reverse Putaway | In-line Print and Apply |

The PALMS™ warehouse control system framework provides the interface for the WMS Software with different AS/RS systems to seamlessly carry out operations in the warehouse, and maintain an incredibly precise degree of inventory control.

An effective inventory control WMS software makes all the difference in offsetting those tiny, pesky margins that inflate costs and inhibit maximum efficiency. With PALMS™ WCS, you have a centralized solution with all the integrations customized for any business scenarios.

Speak to our in-house experts today to increase productivity across your supply chain!

Technoforte Software Private Limited is an ISO 9001:2015 & ISO 27001:2013 certified company engaged in providing high end enterprise solution in the field of Information Technology.

Through Technoforte’s suite of products, the company specializes in helping large and medium sized industries in implementing Business Intelligence solutions, Warehouse Management System, Service, and Warranty Management System and Mobile based Enterprise Level Solutions.

COPYRIGHT © 2024 TECHNOFORTE SOFTWARE PVT. LTD. ALL RIGHTS RESERVED.