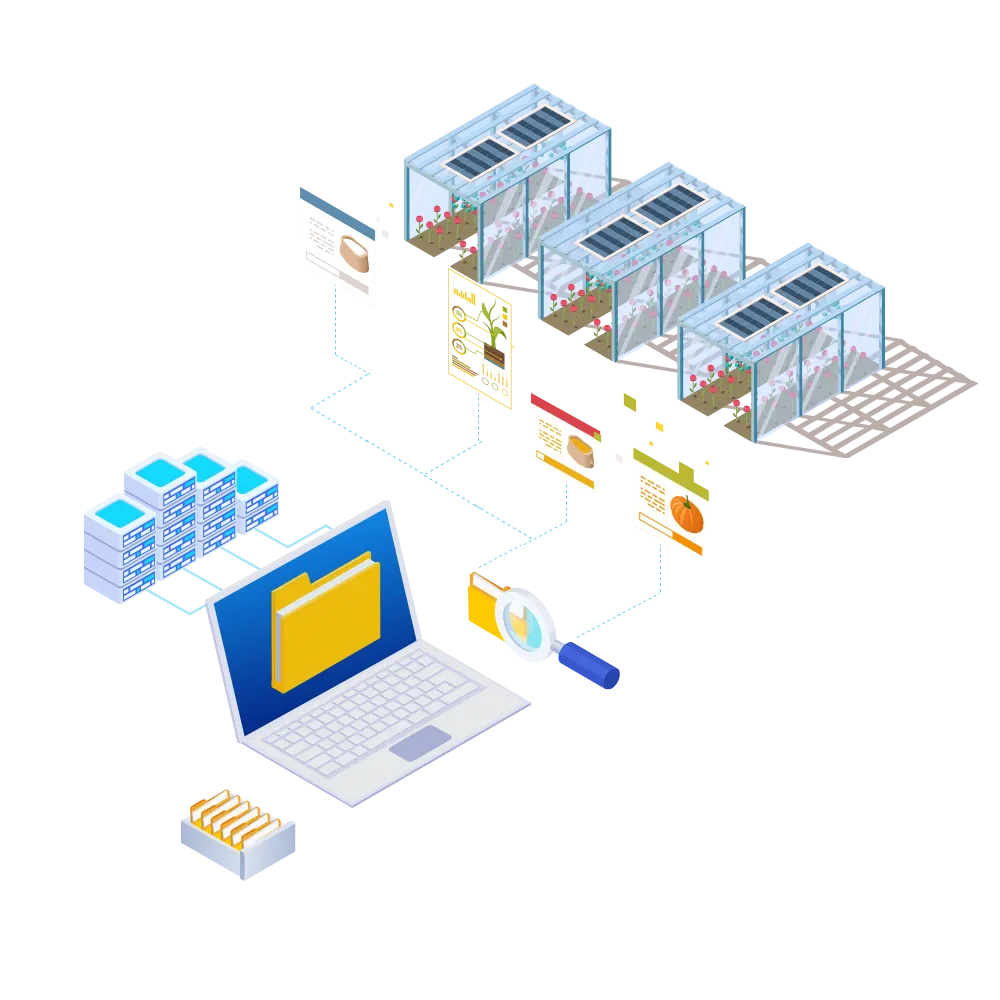

Cold storage system is a warehouse management program that can be applied to help regulate conditions like temperature and humidity levels in warehouses that preserve perishable items like vegetables, fruits, and meat, or products that require special conditions, like pharmaceuticals, cosmetics, plants and textiles.

The management of cold storage warehouses is a complicated process that involves innumerable variables.

A good cold store software has a multitude of capabilities that can manage tasks like inbound and outbound logistics, supplier, agent and customer details, payments, and inventory management.

These functions are simplified when the right software is employed for records, automation and analytics; saving time and cutting down on errors.

With cold storage requiring temperatures as low as 28C, saving on energy costs and maximizing capacity of the warehouse are major concerns.

Mobile racking and drive-in racking are typical strategies used by cold storage warehouses to utilize space as efficiently as possible. However, operational issues can arise out of such strategies and that’s where the WMS comes in.

There are many similar warehousing challenges specific to cold storage management that can be addressed with our top-of-the-shelf WMS.

The mechanism that connects the product to the WMS are the barcodes. Any inaccuracy in this labeling be it expiry dates, specific types or location tags can be catastrophic.

The precision of PALMS™ with the printing and location labeling technology ensures that such scenarios are avoided.

Different items in the cold storage might require different levels of humidity and temperature. Without a WMS, this job might be performed by an operator who has to be physically present at the warehouse at all times.

For optimal space utilization and cost-effective operations, the same location might store multiple commodities requiring different conditions in different chambers. PALMS™ understands this, and even has the specific functionality to create ripening chambers as needed.

Precise information regarding bin location and capacity can be incredibly significant in the management of a cold storage warehouse. Products like fresh produce, especially, may require additional controls like CO2 and humidity. Without accurate data records, it can be difficult to meet HACCP (Hazard Analysis and Critical Control Point) standards.

PALMS™ Agriculture and Cold Store Management System is a module built specifically to meet the needs of the agricultural and cold store industry.

The various unique features of our cold storage system are:

The security features of PALMS™ cold storage software are intricate and robust. Employees can only view the data they are allowed to access.

Our application has special functionality catered to blast freezing and tempering. The WMS extraction command can create an alert when products reach a preset temperature.

The PALMS™ WMS is also able to support multiple allocation strategies:

Cost management becomes easier with PALMS™ because of our cloud-hosted application requiring minimal IT infrastructure and lower upfront costs.

Cloud WMS also means a rapid fulfillment process with a straightforward onboarding process, flexibility and scalability in operations, seamless integration with ERP systems, and a user-friendly, accessible customer experience tailored to cold storage management.

Read more about WMS features here.

Want to optimize your cold storage warehousing processes? Speak to a PALMS expert today!

Technoforte Software Private Limited is an ISO 9001:2015 & ISO 27001:2013 certified company engaged in providing high end enterprise solution in the field of Information Technology.

Through Technoforte’s suite of products, the company specializes in helping large and medium sized industries in implementing Business Intelligence solutions, Warehouse Management System, Service, and Warranty Management System and Mobile based Enterprise Level Solutions.

COPYRIGHT © 2024 TECHNOFORTE SOFTWARE PVT. LTD. ALL RIGHTS RESERVED.