Home » Features

PALMS™ Smart WMS by Technoforte is a Digital Transformation tool for supply chain and warehouse management designed to effectively manage warehouse operations across multiple warehouse locations, and a variety of industry verticals. With PALMS™, businesses are able to harness the software to increase efficiency, reduce costs, and improve the overall fluency of warehouse operations.

Digitizing data using PALMS™ Smart WMS profoundly affects the ease of traceability, compliance with regulations, data insights and visualization. With all data on resources digitally accessible in the application, managers are able to make more informed decisions.

PALMS™ can have a transformational effect on your warehouse, eliminating the need for a physical document library and the risks associated with it. Documentation like supplier invoices, delivery challans, PO copies can all be accessed instantaneously.

The modular architecture of the application allows the customer to “pick and choose” from a rich add-on module repository. This means pricing can be customized to match customer requirements.

PALMS™ Smart WMS has built-in self-learning capabilities that adapt to the specific needs of your business:

Note – all zero-setup recommendations also have associated setups to further fine-tune system recommendations. However, the system also works without any setups by its self-learning capability

The implementation of PALMS™ Smart WMS impacts every aspect of warehouse management to create a “Digital Warehouse”.

The “Digital Warehouse” refers to the transformed warehouse with increased throughput, productivity and efficiency created by PALMS™. The real-time visibility, traceability and analytics offered by the application creates a competitive advantage in today’s challenging business environment.

The “Digital Warehouse” is centered around a number of smart features that put the control of all warehouse activities at your fingertips:

Implementing a Warehouse Management System is one of the most critical decisions for any enterprise with supply-chain-intensive operations. Once implemented, the WMS becomes a backbone for all future warehouse operations across the enterprise. One key decision-making factor is the WMS’s readiness for future requirements. While current requirements may be limited, it cannot be ruled out that requirements will evolve and more complexity will be added to the business operations.

PALMS™ Smart WMS is a highly scalable solution with a rich set of Add-On Modules that can be opted for at any later date, whenever the need arises:

PALMS™ R&D Labs

The PALMS™ Smart WMS Product team is continually enhancing the product features so that you as a customer can rest assured that every update ensures that you stay ahead of the curve. Some of the futuristic features that are currently being worked upon at the PALMS R&D Labs are:

PALMS™ WCS

PALMS™ WCS helps customers integrate our warehouse management system to AS/RS, vertical carousel, and other PLCs.

Standard reports available in PALMS™ WMS:

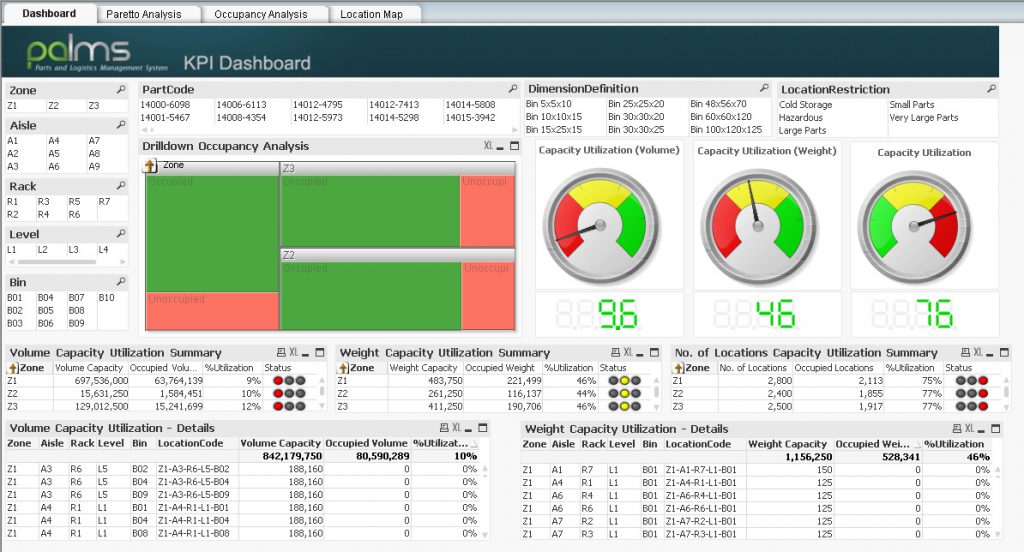

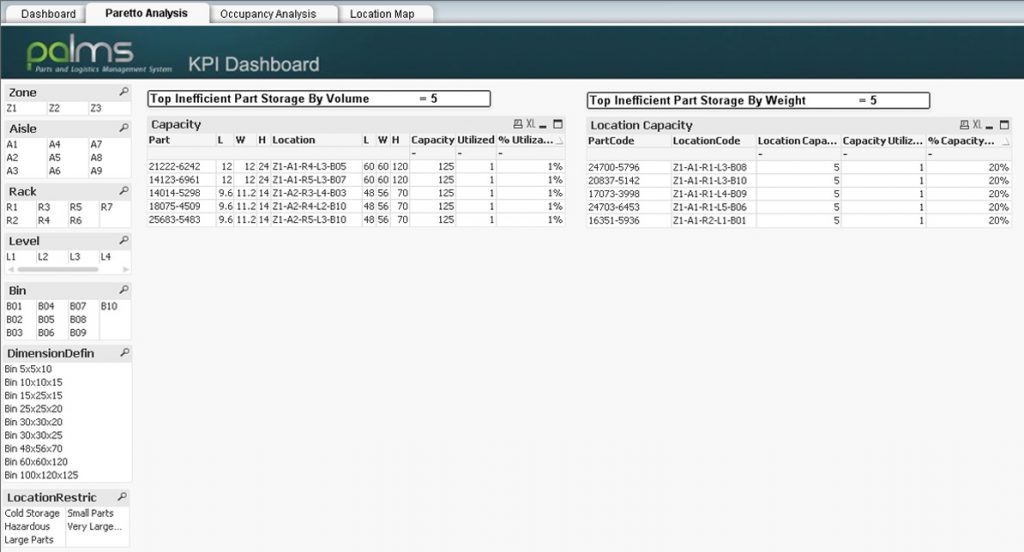

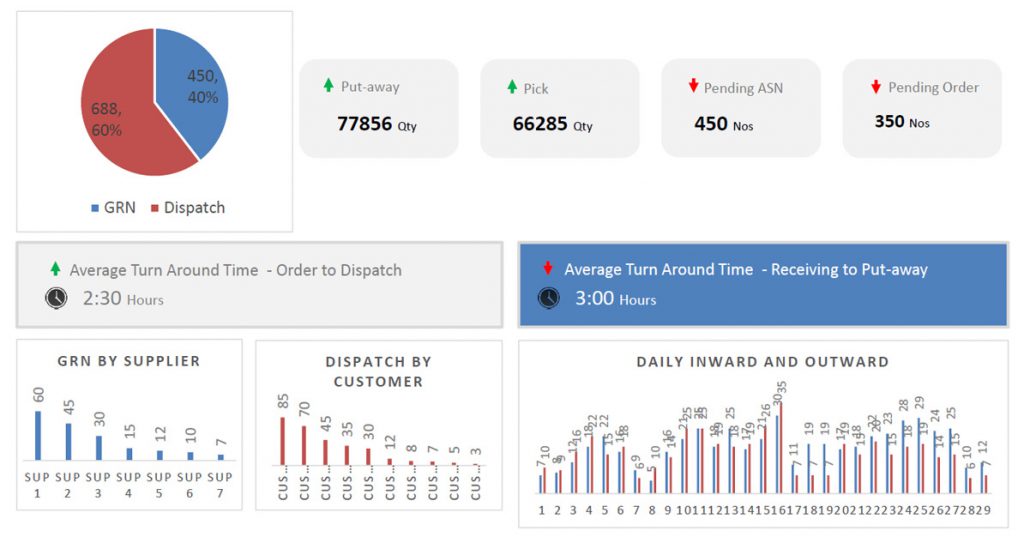

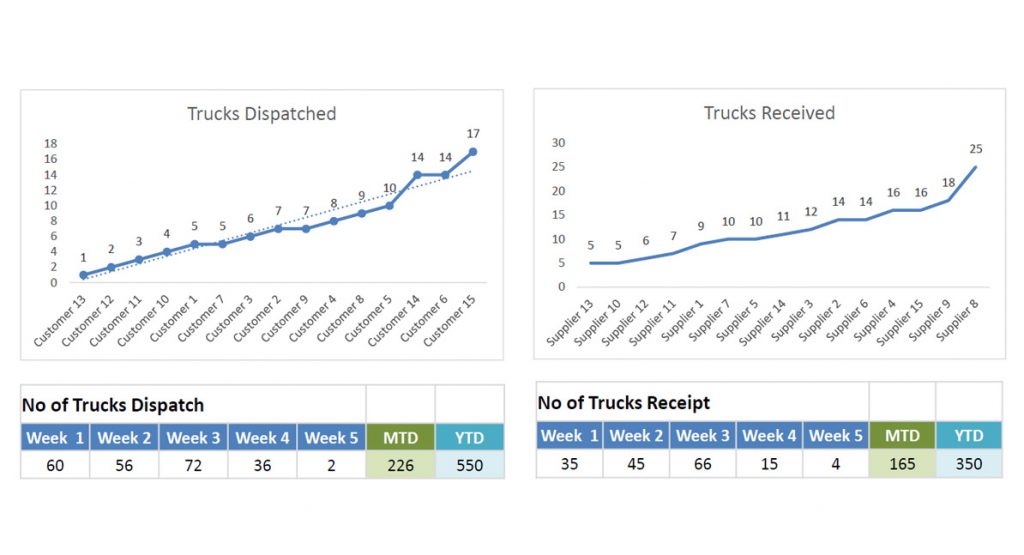

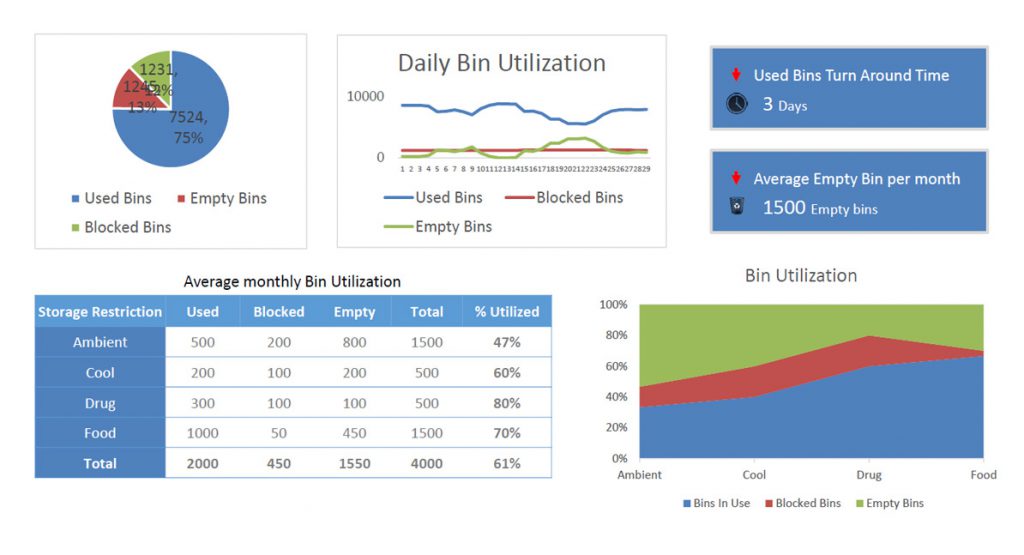

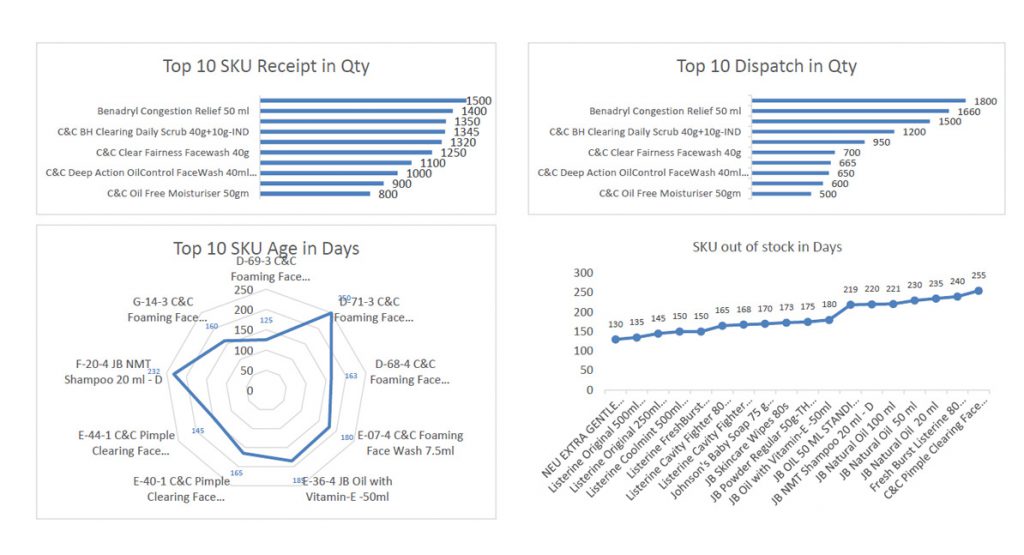

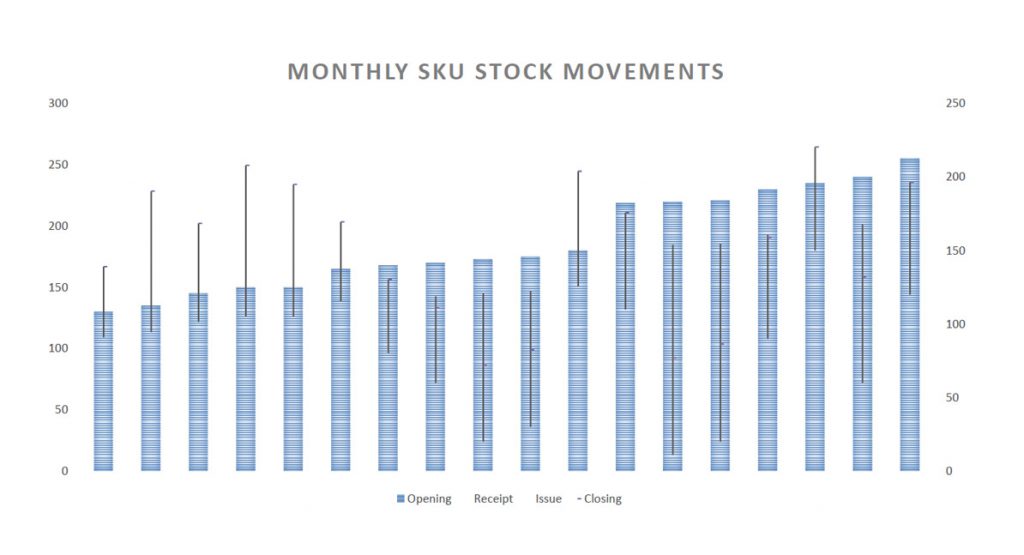

Digitized warehouse data can be utilized for smart analytics. The data collected by PALMS™ is used to create data visualization reports and actionable insights for decision makers.

PALMS™ has 120+ ready-to-use reports available which can deliver insights on a variety of metrics so that your business is able to gauge the fluency of warehouse operations. Frequently searched screens and columns can be saved as a named search.

The aforementioned features make PALMS™ the preferred warehouse management system for large warehouse operators. At the highest levels, areas where Technoforte’s PALMS™ Smart Warehouse Management System shows the greatest ROI are:

01 Efficient Forecasting Algorithms ensure Optimal Inventory Positions resulting in Direct Cost Savings

02 Barcode, RFID and Voice Picking enabled processes for efficient and accurate material movement. Rugged Hand-held terminals with

barcode or RFID functionality can be used for operations such as: receiving, binning/put-away, picking, kitting and packing.

03 Improved Utilization & Tracking of Man Hours through live monitoring dashboards.

04Faster decisions improving the ROI of overall SCM Operations.

05 Empower the business through increased access to holistic, consistent enterprise information

06Improved business performance, increased profitability, streamlined operational efficiency and proactive management of regulatory compliance.

07PALMS™ Smart WMS can be integrated to third party ERP using electronics data interchange (EDI).

08PALMS™ electronics data interchange (EDI) helps companies extend their Warehouse Management System to their customers and suppliers.

09PALMS™ can easily be extended to customers and suppliers using palms portal users

10PALMS™ WCS helps customers integrate the warehouse management system to ASRS, vertical carousel and other PLCs.

We have satisfied customers in many countries – India, UAE, Saudi Arabia, USA, Qatar, Bahrain, Kuwait, Malaysia, Nigeria, Kenya

Speak to our experts today, and find out how PALMS™ can transform your business!

Technoforte Software Private Limited is an ISO 9001:2015 & ISO 27001:2013 certified company engaged in providing high end enterprise solution in the field of Information Technology.

Through Technoforte’s suite of products, the company specializes in helping large and medium sized industries in implementing Business Intelligence solutions, Warehouse Management System, Service, and Warranty Management System and Mobile based Enterprise Level Solutions.

COPYRIGHT © 2025 TECHNOFORTE SOFTWARE PVT. LTD. ALL RIGHTS RESERVED.