The modern warehouse is no longer a dimly lit space of paperwork and manual scanning. Instead, it has become a hub of connected sensors, scanners and robotics that automate tasks and feed data into the warehouse management system (WMS). Recent reports estimate that the global IoT in warehouse management is expected to more than double to about USD 34.68 billion by 2032, growing at a CAGR of ~12.1%.

By linking devices over the Internet of Things (IoT), warehouses gain real-time visibility and control over inventory and workflows. In practice, RFID tags on pallets, smart shelves with built-in sensors and guided robots all report stock levels and equipment status to the WMS. IoT-enabled warehousing means a warehouse that actively tracks its own activities and adjusts in real time, rather than relying on slow manual updates. In this blog, we will look into how IoT-enabled warehousing helps businesses stay ahead in the industry.

What is IoT (Internet of Things)?

IoT refers to networks of smart devices that collect and exchange data. In the warehouse, these devices range from RFID tag readers and motion detectors to temperature sensors and autonomous vehicles.

When integrated with a WMS, they turn the system into a Smart WMS. It is a software platform that continuously optimizes storage and fulfillment based on live data.

For example, if sensors report that a product’s shelf is empty, the WMS can automatically trigger a reorder or move stock from another zone. If a forklift’s vibration sensor shows a potential failure, maintenance can be scheduled before it breaks down. By linking IoT data to warehouse software, businesses create a responsive, self-correcting operation.

How IoT Integrates with Warehouse Management Systems

A Warehouse Management System (WMS) acts as the central coordination point for all warehouse activities. In an IoT-enabled setup, the WMS integrates with countless devices, from scanners to conveyors, to capture real-time information.

In effect, the WMS becomes the ‘brain’ that connects staff, equipment and inventory. A modern WMS continuously captures real-time information about inventory movement, equipment status and order progress by integrating with IoT sensors, RFID tags and automated machinery. This means every scan, signal, or sensor reading is sent directly into the WMS database.

Technically, IoT devices send data through wireless networks (often 5G or Wi-Fi) to the WMS or to cloud platforms linked to the WMS. For example, a temperature sensor in a cold-storage zone might transmit its readings to a cloud-based analytics engine, which then updates the WMS database. Barcode scanners and RFID readers feed each item’s ID and location directly into the WMS as goods move through the facility.

Over time, the WMS aggregates all this data, applies analytics or AI to it and then issues instructions or alerts. For instance, the WMS might adjust pick paths, reslot fast-moving items to the front of an aisle, or direct autonomous robots to handle a backlog of orders. The result is a highly automated workflow where the WMS and IoT devices form a closed feedback loop: devices update the system and the system commands the devices.

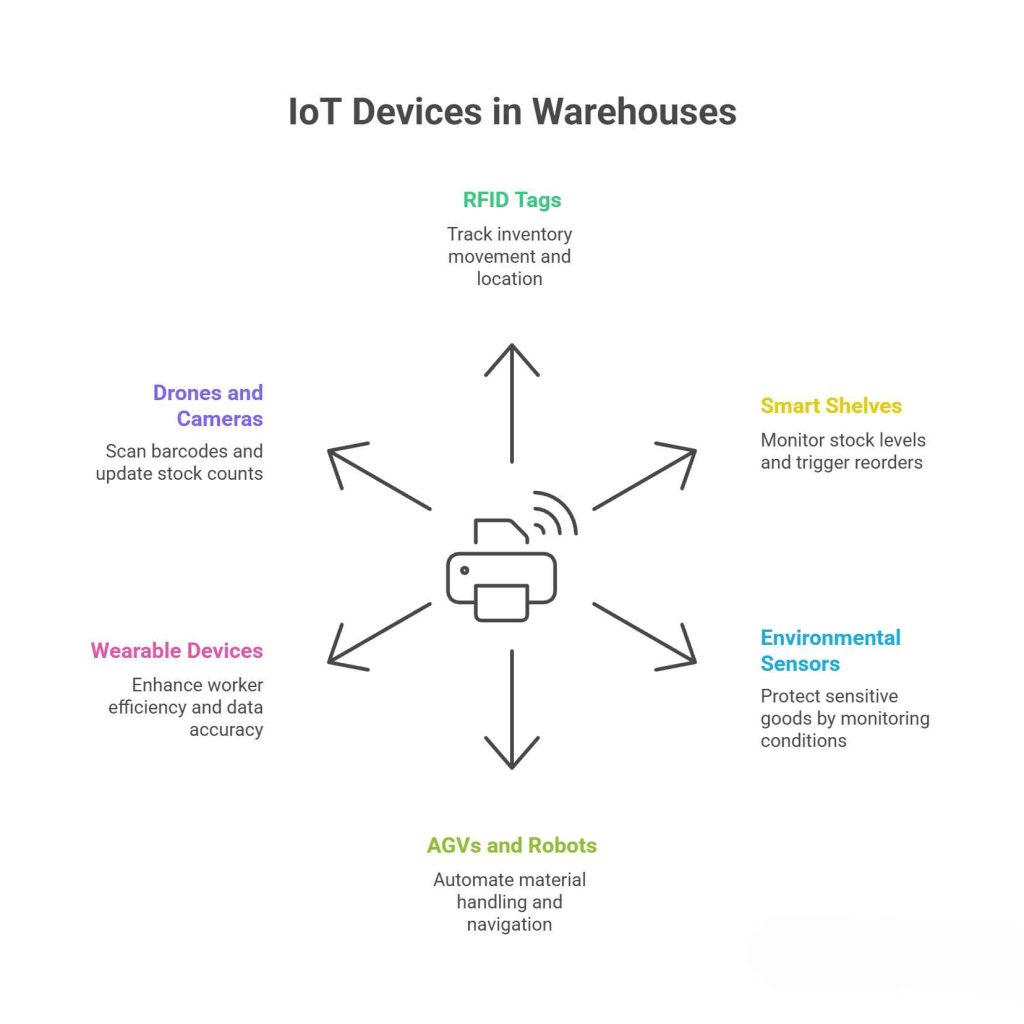

Key IoT Devices and Technologies in Warehouses

IoT-enabled smart warehouses use a variety of devices and sensors to track inventory and conditions. Common components include:

RFID Tags and Barcode Scanners

These give each pallet or item a unique ID and location, automatically updating the WMS. RFID antennas and handheld readers scan items on the move, so the system always knows what is where.

Smart Shelves and Weight Sensors

Shelving units may have built-in load sensors that measure stock weight. When the weight drops below a threshold, the shelf signals the WMS that inventory is low and a replenishment is needed. This automates cycle counts and reorders.

Environmental Sensors

These devices monitor temperature, humidity and air quality to help protect sensitive goods. For example, sensors in a cold storage room continuously report conditions to the WMS, which can trigger climate control adjustments or alerts if levels drift out of range.

Automated Guided Vehicles (AGVs) and Robots

Self-driving carts, conveyors and robotic arms carry goods around the warehouse. IoT enables these machines to navigate and coordinate. A WMS sends tasks to the robots, while the robots send back status updates. For instance, Amazon and other companies deploy fleets of AGVs that move inventory between shelves and packing stations under WMS control.

Wearable devices

Workers may use IoT wearables like smart glasses, scanners or wristbands. For example, smart glasses can display picking instructions and confirm items visually, while communicating live data to the WMS. Such devices help employees work hands-free and feed exactly what they pick or pack into the system.

Drones and Vision Cameras

In large warehouses, drones fly down aisles to scan barcodes or check stock. Machine-vision cameras mounted on forklifts or ceilings can also recognize items and update counts in the WMS in real time.

Each of these devices has network connectivity (often 5G, Bluetooth, or Wi-Fi) so that no matter where stock moves in the facility, the WMS is updated instantly.

Benefits of IoT-Enabled Warehousing

Implementing IoT alongside a WMS unlocks many gains for logistics and warehouse operations. Key advantages include:

Data-driven Decisions

With live data streaming in, managers can avoid stockouts and overstocks. For example, if the WMS sees that a popular item is nearly out, it can automatically place an order or move inventory. This real-time visibility enables managers to make informed decisions about inventory replenishment and order fulfillment.

Greater Efficiency

IoT devices automate routine tasks. Inventory counts become continuous and invisible, instead of manual cycle counts. Conveyor and sorting systems work automatically based on IoT triggers.

Overall, workflows speed up and human effort focuses on higher-level tasks. A cloud WMS integrated with IoT ensures tasks are optimized, so employees can focus on higher-value work. Therefore, processes like receiving, picking and packing run faster and with fewer bottlenecks.

Faster Order Fulfillment

Because inventory locations and status are always up-to-date, orders move through the system faster. Optimized pick paths and automatic batching (guided by IoT data) mean faster picking. For example, DHL’s use of smart glasses (an IoT device for workers) raised picking productivity by 25%. Overall, shipments go out sooner and delivery promises can be met with confidence.

Cost Savings

IoT enables predictive maintenance and waste reduction. Sensors on equipment catch issues early, so repairs can be scheduled before a breakdown stops the line. This cuts downtime and maintenance costs. Smart lighting and climate control (triggered by IoT occupancy and environment data) also trim energy bills. By automating inventory checks, warehouses reduce shrinkage and overstock. The net effect is lower operating expenses and higher uptime.

Improved Safety

IoT strengthens security and accident prevention. Cameras and motion sensors can lock down areas if a hazard is detected. Gas and temperature sensors alert if conditions become unsafe.

For example, wearables and wear-ready devices can notify personnel of spills or equipment malfunctions in real time, preventing injuries. The WMS can then react, for instance, by rerouting traffic away from the hazard.

Enhanced Inventory Accuracy

In traditional warehouses, errors come from delayed updates or manual mistakes. IoT virtually eliminates this. Every item scan or sensor reading goes straight into the WMS. This eliminates guesswork and manual checks. Companies see far fewer mispicks and “on-hand” inventory in the WMS matches reality. In practice, businesses often see drastically fewer stockouts and less excess stock.

Implementing IoT with Your WMS: Best Practices

Connecting IoT to a WMS requires planning and the right strategy. Industry experts recommend a phased approach with clear goals. Key steps include:

- Define clear objectives: Know what you want to achieve and measure progress against those goals.

- Assess existing systems: Ensure your current WMS and IT infrastructure can handle IoT data. This may involve upgrading network bandwidth or moving to a cloud WMS that scales.

- Select the right devices: Pick sensors and tags that match your needs (e.g. RFID for pallets, temperature sensors for cold zones). Consider range, battery life and compatibility.

- Start small with a pilot: Test the solution in a limited area or process. For example, trial smart shelving in one aisle, or a few IoT-enabled forklifts. This verifies the ROI and helps fine-tune integration before full rollout.

- Secure data and networks: Every IoT device is a potential cyber-entry point. Use encryption, strong authentication and network segmentation to protect warehouse systems.

- Plan for scalability: Design the system so you can easily add more sensors or expand coverage. For instance, use cloud-based platforms that automatically handle extra device data as you grow.

- Train staff: Even the best tech needs human support. Train warehouse teams on how to use IoT tools (e.g. scanning procedures with smart glasses) and how to interpret the new data dashboards.

- Iterate and improve: Once live, monitor the IoT data closely. Use analytics to find bottlenecks or unexpected issues. Update workflows in the WMS based on what the data shows (for example, re-route a picking path if it remains congested).

Future Trends in Smart Warehousing

The synergy of IoT and WMS is still evolving. Upcoming advances promise to push performance even further:

- 5G and Connectivity: Next-generation 5G wireless networks are rolling out in warehouses. Because 5G offers ultra-fast, low-latency links, IoT devices can send data instantly and reliably, even in large facilities. This allows many more sensors and robots to operate together without delays.

- Edge Computing: Some processing will move to the edge (on-site devices) rather than the cloud. This means decisions can be made even faster. For example, a sensor could locally trigger a robotic arm to act immediately when an item is placed, rather than waiting on cloud analysis.

- Robotics and Automation: IoT will increasingly guide autonomous machines. Integration of IoT with robotics leads to more efficient operations. Expect more drones doing inventory, more AMRs (autonomous mobile robots) working in tandem, all coordinated in real-time by the WMS.

- Digital Twins: Virtual models of the warehouse will mirror real operations. Every sensor reading could update a digital twin of the facility, letting managers simulate changes before applying them for real.

- Augmented Reality (AR): AR devices (like smart glasses) will overlay IoT data on a worker’s view. For instance, pickers might see arrows pointing to the correct bin with live stock info, all guided by the WMS. This hands-free guidance further speeds tasks.

Experience Smarter Warehousing with PALMS™ Smart WMS

Integrating IoT devices with a Warehouse Management System turns traditional warehouses into smart, data-driven environments. With real-time inputs from sensors, scanners and automated equipment, the WMS becomes the command center that continuously optimizes workflows, minimizes errors and boosts operational efficiency.

Our proprietary technology PALMS™ Smart WMS brings this vision to life, connecting every device, process and person in your warehouse through the power of IoT. From real-time tracking and predictive maintenance to automated replenishment and data-driven decision-making, PALMS empowers you to achieve total visibility and control over your warehouse operations.

Connect with PALMS™ Smart WMS today to transform your warehouse into an intelligent, future-ready ecosystem.