Modern supply chains are under constant pressure to deliver products faster, more accurately and at lower costs. To meet these demands, warehouses are increasingly turning to artificial intelligence (AI) and machine learning (ML). AI-driven solutions promise to transform warehouse operations by turning data into actionable insights. According to McKinsey & Company, warehouses that leverage AI-powered tools can unlock an additional 7–15% of warehouse capacity.

These technologies integrate with warehouse management systems (WMS) and automation to streamline tasks and cut operational costs. They also support fully automated dark warehouse operations, where AI and robotics handle tasks around the clock. In this blog, we will look into how AI and ML help with demand forecasting, efficiency and more in warehouses.

What is a Dark Warehouse?

A dark warehouse is essentially a fully automated facility designed to operate with little to no human presence. In these environments, robotics and advanced automation systems take over the core functions of warehousing—receiving, storage, picking and shipping. Goods may be stored in automated storage and retrieval system (AS/RS) grids, picked by robotic arms and transported by autonomous mobile robots (AMRs). Behind the scenes, a warehouse management system (WMS) orchestrates operations, dynamically adjusting stock placement, dispatching robots and ensuring workflows run smoothly.

How a Dark Warehouse Operates

In a typical dark warehouse, incoming goods are unloaded and sorted by conveyors or robotic arms before being placed into storage bins. Autonomous shuttles transport these bins to and from vertical rack systems, creating dense and efficient storage.

When an order is placed, the WMS immediately dispatches robots to retrieve the items and deliver them to automated packing stations. Every step is coordinated by software powered by real-time data. Since these facilities run 24/7 without breaks or shift changes, they can process a far higher volume of orders than human-operated warehouses.

Dark warehouses combine the power of AI, robotics and intelligent WMS to deliver unmatched efficiency, scalability and cost savings. By removing many of the constraints of human-dependent operations, they represent the next frontier in logistics and supply chain management.

Key Applications of AI and ML in Dark Warehouses

Artificial intelligence is no longer just a futuristic concept, it’s already transforming how warehouses operate on a daily basis. Here are some of the most impactful applications:

- Demand Forecasting: Machine learning models analyze sales trends, seasonality and other factors to predict product demand. Accurate forecasts let warehouses keep the right inventory on hand and reduce excess stock.

- Inventory Management: AI-powered WMS can automate replenishment and re-slotting. For example, systems may move fast-selling items to accessible racks and reorder stock when levels drop, cutting carrying costs.

- Order-Picking Optimization: AI optimizes picking routes using real-time order data and warehouse layouts. By clustering commonly ordered items and adjusting slotting, AI reduces travel distance, shortening cycle times and cutting errors.

- Predictive Maintenance: IoT sensors feed equipment data into ML models to forecast failures. AI-driven maintenance scheduling prevents breakdowns and unplanned downtime, extending machinery life.

Role of WMS and IoT in Dark Warehouses

A warehouse management system (WMS) functions as the central brain that connects people, machines and data. By integrating with Internet of Things (IoT) devices, such as sensors, RFID tags and automated equipment, a modern WMS can continuously capture real-time information about inventory movement, equipment status and order progress.

Artificial intelligence enhances this process by analyzing the incoming data and turning it into actionable decisions. For instance, the WMS might automatically re-slot fast-moving items closer to packing stations to reduce travel time or direct autonomous mobile robots (AMRs) to balance workloads across the facility. The result is a warehouse that doesn’t just store goods, but actively drives efficiency through data-driven operations and smart automation.

Benefits of AI in Dark Warehousing

The integration of AI, machine learning and automation is redefining warehouse performance. Here are some of the key benefits:

Labor Savings

Repetitive tasks such as picking and sorting can now be handled by robots and intelligent software. This reduces dependency on manual labor, easing hiring pressures in a sector often challenged by workforce shortages. As a result, companies can lower staffing costs while allowing human workers to focus on more strategic tasks.

Higher Productivity

AI-driven systems operate around the clock, ensuring steady, 24/7 output. For example, AI tools can unlock additional warehouse capacity by optimizing labor and equipment usage.

Inventory Efficiency

Smarter forecasting and AI-powered inventory controls help warehouses maintain the right stock levels. By better predicting demand and dynamically adjusting inventory, businesses can reduce carrying costs and avoid both overstocking and stockouts. McKinsey estimates that AI can cut inventory levels by 20–30%, directly boosting profitability.

Energy and Resource Efficiency

Dark warehouses are designed to minimize waste and resource use. AI can automatically dim lights or adjust temperatures in unused zones, while automation enables denser storage layouts that save valuable space. Equipment can also power down when idle, resulting in lower utility bills.

Error Reduction

Automated processes guided by AI and robotics significantly reduce human error. Machine vision and precise robotic systems improve picking accuracy, ensuring that inventory data remains up to date. Dark warehouses, in particular, maintain exceptionally accurate records without relying on frequent manual recounts.

Flexibility and Scalability

AI and automation make warehouses more agile in responding to demand spikes. During seasonal peaks, businesses can scale quickly by adding a few more robots or extending automated shifts—without the delays associated with hiring and training temporary staff. This adaptability ensures smooth operations even during high-volume periods.

Together, these benefits translate into faster fulfillment, lower operating costs and stronger customer satisfaction.

Challenges and Considerations

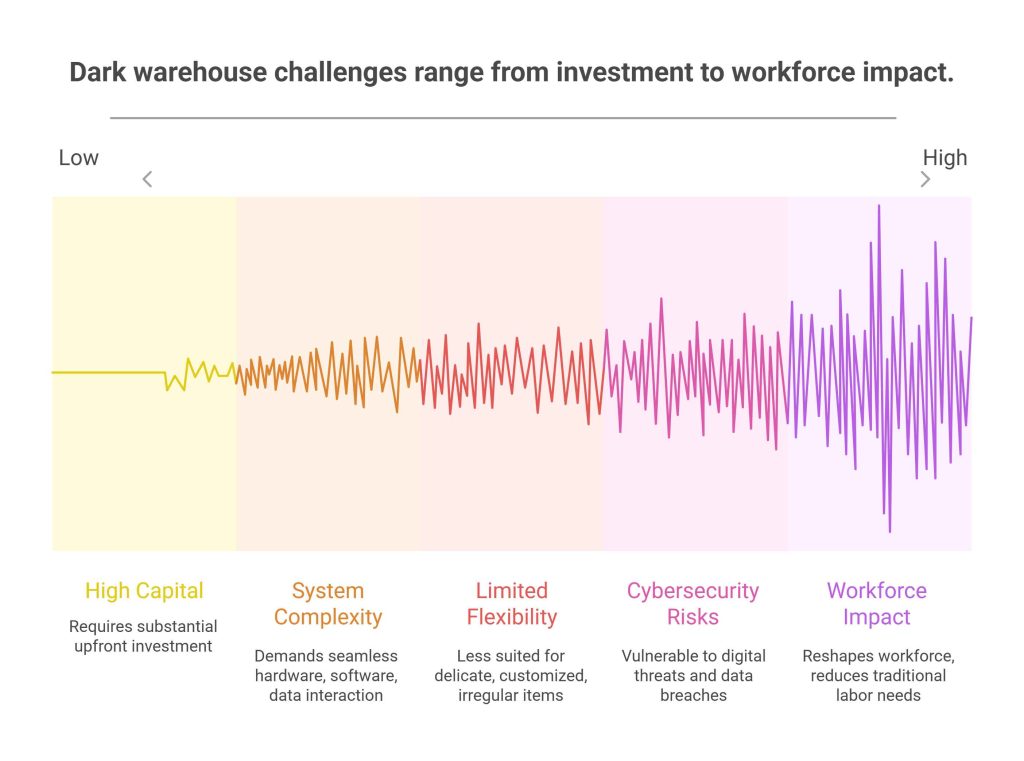

While AI-driven automation and dark warehouses promise significant efficiency gains, they also introduce challenges that companies must carefully navigate. Below are some of the key hurdles and practical solutions to overcome them.

High Capital Investment

Implementing a dark warehouse requires a substantial upfront investment. Robots, sensors, IoT devices and AI-powered software come with steep price tags and the costs don’t end there. Designing, testing and integrating these systems into an existing supply chain requires specialized expertise and often custom solutions. For many businesses, particularly small and mid-sized players, this level of investment can pose a significant barrier to adoption.

Solution: Companies can mitigate costs by adopting a phased implementation strategy. They can start with partial automation in high-impact areas (e.g., order picking or replenishment) before scaling to full automation.

Complexity of System Integration

Building a fully automated warehouse is not as simple as purchasing robots. Dark facilities rely on the seamless interaction between hardware, software and data systems. Any misalignment, whether in WMS, IoT sensors, or robotic workflows, can create bottlenecks or system failures. Also, warehouses must prepare for exceptions, such as irregularly shaped goods, returns, or damaged items. If these scenarios are not preprogrammed into the system, operations may come to a halt.

Solution: Conduct extensive simulation and testing before deployment, using digital twins to model warehouse operations and identify bottlenecks. In addition, designing a hybrid approach where human workers handle edge cases while automation manages standardized processes, ensures resilience when exceptions occur.

Limited Flexibility with Certain Goods

Dark warehouses excel at handling standardized, high-volume products, but they are less suited for delicate, customized, or irregular items. For example, fragile goods that require careful handling or items that do not fit into automated bins may require manual intervention. This limitation makes dark warehousing more practical for industries with predictable product types, such as e-commerce, retail and consumer goods, rather than sectors with high product variability.

Solution: Adopt a hybrid warehouse strategy where dark warehouse zones manage high-volume SKUs, while separate manual or semi-automated areas handle sensitive or unusual products.

Cybersecurity Risks

As warehouses become more connected, they also become more vulnerable to digital threats. Every IoT device, cloud platform and software integration creates a potential entry point for hackers. A breach could compromise sensitive data, disrupt operations, or even halt fulfillment entirely.

Solution: Implement multi-layered cybersecurity protocols, including end-to-end encryption, regular system audits and intrusion detection systems.

Workforce Impact

Automation inevitably reshapes the workforce. While robots take over repetitive, low-skill tasks, this can reduce the need for traditional warehouse labor.

Solution: Rather than eliminating staff, companies can reskill employees into higher-value roles such as robotics maintenance, system supervision and data analysis. Offering structured training programs and clear career pathways helps workers embrace automation as an opportunity rather than a threat.

How Palms Smart WMS Can Help

Transitioning to smarter, more automated warehousing requires the right technology backbone and that’s where Palms Smart WMS comes in. By combining AI-driven insights, machine learning and automation, we enable warehouses to operate with greater intelligence and efficiency.

Our PALMS™ Smart Warehouse Management System allows businesses to leverage advanced tools for demand forecasting, intelligent inventory control and optimized picking strategies. With IoT data feeding into real-time analytics, Palms Smart WMS gives managers complete visibility into warehouse performance, helping them reduce costs, minimize errors and accelerate fulfillment cycles.

Whether a business is aiming for the long-term vision of a fully automated dark warehouse or simply wants to enhance its current operations with smarter workflows, we provide scalable solutions needed to make the transition smooth, efficient and sustainable.

Conclusion

Artificial intelligence and machine learning are no longer optional add-ons for warehouses, they are becoming the foundation of modern supply chain operations. From predicting demand and optimizing inventory to enabling fully automated dark warehouses, these technologies are redefining what efficiency looks like in logistics. With the rise of dark warehouses, facilities can now operate continuously, around the clock, with higher throughput, lower labor costs and reduced energy consumption.

Adopting these solutions requires careful planning, investment and change management. But for supply chain and technology leaders, the long-term payoff is clear: smarter, more agile warehouses that not only cut costs but also give businesses the speed and flexibility needed to stay competitive in an evolving marketplace.

Ready to take the next step toward smarter, more efficient warehousing? Connect with Palms Smart WMS today; we can help you make that transformation seamlessly.