Investing in yard management and a logistics network is a significant commitment for businesses and a crucial factor in gaining a competitive edge. Recent years have shown considerable fluctuations in demand and supply, highlighting the necessity for precise real-time coordination of all logistical processes to optimize service levels and asset utilization.

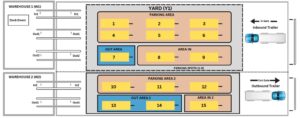

Among the various components of logistics, yard operations are frequently neglected. These involve the physical areas within warehouse premises, distribution centers, and manufacturing plants where incoming and outgoing shipments are managed. Apart from static infrastructure like gates and loading docks, the yard comprises dynamic elements such as trucks, trailers, cargo, and staff.

As businesses strive to enhance their logistics networks, they must recognize the significant strategic and financial benefits of this intricate and costly domain. Through efficient optimization of the monitoring, coordination and scheduling, companies can lower expenses to boost profitability, while simultaneously improving the quality of service.

With increasing awareness of the value of yard optimization, the demand for solutions in dock and yard management is on the rise. Initially valued at $3.1 billion in 2021, this market is anticipated to expand to $7.82 billion by 2030, indicating a yearly growth rate of 11.26%.

Video: What is Yard Management? How Does It Improve Warehouse Operations?

Understanding Yards

A yard typically serves as an extension of the warehouse, making it essential for inventory control.

Upon check-in of a trailer, it might require guidance to an assigned dock door or an unoccupied one within the yard. If no dock doors are available, it may be directed to an empty parking spot within the yard. The information channel should be managed to enable the system to automatically route the trailer according to a predetermined schedule.

What is Yard Management?

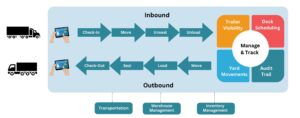

Yard management involves the organization, coordination, and guidance of various assets, including incoming and outgoing trucks, trailers, shipments, personnel, and other resources, within the dock and yard areas of a facility.

To attain a competitive edge, companies must pursue numerous objectives: optimizing inventory control, reducing inventory levels, shortening order processing times, enhancing fill rates, and streamlining the flow of inventory both within warehouse premises and across yard spaces. Through effective yard management, your company can optimize the flow of inventory within the yard areas of manufacturing facilities, warehouses, or distribution centers.

You can establish the necessary entities for yard management and capture real-time transactions occurring within the yard. This allows for tracking the whereabouts of trailers within the yard and empowers yard personnel to efficiently move trailers from parking areas to docks to fulfill orders.

The complexities of yard management are on the rise, and recent disruptions in the supply chain have prompted many organizations to scrutinize their yard operations for opportunities to enhance efficiency.

What are the goals of dock & yard management?

- Efficient operation through time-optimized process chains

- Enhanced capacities and productivity

- Access to real-time information

- Quicker dispatching of trucks

- Enhanced transparency across all processes

- Cost-cutting measures

Yard Management Challenges

Yard management poses unique challenges for each organization, contingent upon factors such as company size, yard size, the range of products present, among others. Through surveys with yard operations personnel around the world, the following key issues have emerged:

Inadequate Trailer Visibility

Yard teams face difficulties in tracking available trailer assets within the yard (and potentially inventory), resulting in inefficient trailer movement, increased costs, and reduced efficiency in operations. The inability to monitor vehicle locations within the warehouse adds to the disorder and inefficiency.

Insufficient Shipment Visibility

Yard teams lack comprehensive foresight regarding the arrival times of trucks for loading or unloading, leading to suboptimal utilization of the yard and its assets. This situation also exacerbates gate congestion and significantly raises demurrage/detention fees. Furthermore, there exists a dearth of visibility concerning backorder fulfillment rates, cross-docking vehicles, and dock operations, including dock-in, operation start, operation end, and dock-out times.

Process Misalignment

Transportation, warehouse, and yard processes are often overseen through disparate yard and dock management systems, companies, or tools that lack dynamic updates or digital maintenance, fostering reactive operations. Consequently, stakeholders lack real-time insights, resulting in inefficient utilization of warehouse dock doors, labor, and equipment, along with increased expenses. Additionally, inadequate utilization of transportation resources leads to prolonged wait times, elevated costs, and delays, potentially straining customer relationships.

Yard Jockey Inefficiency

A deficiency in understanding yard operations leads to ineffective deployment of yard jockeys and an inability to monitor operations for safety and compliance. This deficiency contributes to escalated violations and expenses, as well as squandered jockey labor and deficient planning.

Benefits of Yard Management

Trailer yards often become opaque areas within the supply chain due to limited visibility. Yard management software addresses this issue by providing clarity on the whereabouts of trailers and shipments. By implementing yard management software, manufacturing, distribution, and asset-intensive companies can enhance their order fulfillment and logistics operations by extending visibility and automating processes within the yard. This leads to improved productivity and decreased costs.

Key benefits include:

– Enhanced trailer management and visibility across various facilities and the entire enterprise.

– Streamlined dock operations through collaborative dock scheduling.

– Decreased expenses linked to stock-outs, detention, and demurrage.

– Improved fulfillment and logistics through integrated warehousing and transportation.

– Increased throughput for both the yard and serviced facilities.

Effective coordination of all operations through dock and yard management prevents lengthy queues at gateways, thereby reducing costly periods of inactivity, as logistics operations are interconnected in an efficient network. In essence, dock and yard management guarantees heightened safety, decreased overall cost of ownership, and enhanced throughput. The flow of traffic within the facility is economically organized, facilitating optimal utilization of the infrastructure. With dock and yard management, all data is digitally accessible in real-time, facilitating rapid and seamless communication. Additionally, yard management facilitates optimized resource employment and effective coordination of all logistical activities.

Yard Management with PALMS™ Smart WMS

Extend your supply chain visibility into yard operations with the yard management module in PALMS™ Smart WMS. PALMS™ Yard Management offers the following advantages to enhance the management and efficiency of your yard operations:

Real-time Location and Status Updates

PALMS™ Yard Management provides up-to-the-minute location and status updates for trailers, parking spaces, and dock doors, ensuring smooth yard operations.

Yard Transaction Management Support

PALMS™ Yard Management allows for the efficient management of yard transactions such as check-ins, check-outs, sealing and unsealing operations, and trailer movements within the yard.

Business Event Alerts/Notifications

Manage and receive alerts/notifications during yard warehouse operations for various business events, including:

Check-ins:

– Notifications for late/early/on-time appointments for checked-in equipment

– Validation of seals upon check-in

– Identification of incorrect equipment for pre-scheduled appointments

Yard Scheduling:

– Appointment checks for equipment within the yard

– Notifications for past-due appointments for equipment within the yard

Yard Moves:

– Notifications for past-due appointments when initiating yard moves

Additional Benefits Include:

– Scheduling and maintenance of appointments for incoming and outgoing trailers

– Facilitation of shipping and receiving materials between warehouses via the yard

– Ensuring liability tracking by supporting cost and general ledger (GL) accounting for trailers and their contents

– Enhanced visibility into yard inventory

Yard operations can be streamlined using PALMS™ Smart WMS by implementing the functionalities in three different phases:

Phase 1

- Vehicle-in and vehicle-out-related functions

- Registering the vehicle as soon as it arrives at the warehouse. This includes vehicle details, vehicle number, vehicle type, gross weight or net weight, checklist parameters based on the vehicle type, driver details like driver name, license details, identification details, phone number

- Identifying whether the vehicle has arrived for loading, unloading, or both.

- Generation of a gate-in pass

- Establishing parking lot docks and cross-stuffing areas

- Tracking of the vehicles within the warehouse

- Movement of vehicles from dock to dock, dock to parking, parking to dock, and parking to parking

- Dock management in terms of dock in time, operation start time, operation end time, dock out time

- Ability to load or unload vehicles at multiple docks

- Capturing vehicle out information, gross weight and net weight of the vehicle, checklist parameters based on vehicle type, gate outputs

Phase 2

- Automatic capturing of vehicle registration numbers using a license plate reader

- Vehicle visualization screens for expected vehicles, delayed vehicles, and vehicles in-premises, dock status, parking lot status, back order fulfillment rate vehicle-wise, cross-dock fulfillment rate vehicle-wise

- Driver address system to communicate with drivers involving

- SMS facility to inform drivers about operations

- An artificial intelligence-driven automated voice-based public address system to communicate with the driver

- Driver information dashboard at driver resting area

Phase 3

- Creation of cross-stuffing instructions involving:

- One source vehicle to one destination vehicle

- Multiple source vehicles to multiple destination vehicles

- Multiple source vehicles to one destination vehicles

- Execution of cross-stuffing instructions

- Integration with way bridge for capturing vehicle weight automatically during vehicle in and vehicle out

- Automated dock or parking lot assignment based on vehicle time

- Automatic prioritization suggestion based on cross dock fulfillment criteria, back order fulfillment criteria, vehicle aging

After the three-phase implementation of PALMS™ Yard Management, warehouse managers will be able to gain complete visibility of yard and vehicle operations, view metrics across the multiple warehouse locations, create dashboards for critical operations, make timely decisions based on the identified KPIs, decrease turnaround time for vehicles, reduce demurrage charges and increase the overall efficiency of warehouse operations. Besides yard management, PALMS™ Smart WMS also offers improvements in a number of other areas, for example, reducing the number of backorders, and improving storage allocation through ABC analysis.

Speak to our experts today and begin the digital transformation of your warehouses with PALMS™ Yard Management & PALMS™ Smart WMS!

08/04/24