03/11/2023

In the conventional approach to inventory management, retailers buy products from suppliers in advance and assume responsibility for unsold items. However, an alternative supply chain strategy transfers the burden of inventory costs from retailers to suppliers. This consignment inventory model involves the manufacturer, wholesaler, or supplier retaining ownership of the goods until the retailer successfully sells them to customers. In this scenario, the retailer pays the supplier only for the sold goods and can return any unsold items.

This supply chain model is often adopted by retailers with limited financial resources, particularly for expensive, slow-moving products. It offers retailers protection against the risk of investing in items with uncertain customer demand, as they do not incur losses on unsold inventory. Simultaneously, it provides suppliers with greater control over the sales channels, pricing, and alignment with their brand identity.

What is Consignment Inventory?

Consignment inventory is a supply chain approach where a retailer displays products for sale, but the supplier retains ownership until a customer makes a purchase. Since the retailer doesn’t purchase the inventory upfront, unsold items can be returned. This model is commonly used for items like seasonal products (e.g., holiday decorations) and perishables like produce.

For instance, a supplier of Christmas decorations might agree with a large retail store to offer its products from October to December. The store doesn’t pay for the decorations in advance; payment only happens when customers buy the products during that period. In January, any unsold items are returned to the supplier.

Vendor Managed Inventory (VMI) vs Consignment

Vendor managed inventory (VMI) and consignment inventory are often conflated, however, this is a common misconception.

With vendor-managed inventory (VMI), the supplier takes responsibility for managing the retailer’s stock levels. In some cases, it may include checking inventory levels manually and adjusting them whenever necessary; in others, the retailer will send stock updates at predetermined intervals and the vendor restocks appropriately.

Consignment inventory differs from this as the retailer retains responsibility for ensuring stock is at appropriate levels for their business.

The Consignment Inventory Process

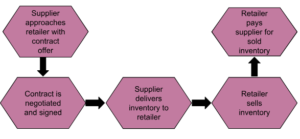

In the consignment inventory management process, the supplier (consignor) negotiates terms with the retailer (consignee). The contract covers the item cost, shipping fees, return procedures, inventory management, deposit or commission requirements, and liability for lost or damaged products.

Once both parties agree, the supplier delivers the inventory to the retailer, earning money only when items are sold. The retailer’s profit depends on the set prices. Unsold inventory can be returned to the supplier without penalties.

How to Manage Consignment Inventory

Effective management of consignment inventory is crucial for both suppliers and retailers to maintain tight control over their products. For organizations dealing with a mix of consigned and non-consigned items, inventory management can be a complex task. Some still rely on slow and unreliable spreadsheet or paper-based systems, hindering collaboration between vendors and retailers.

Numerous warehouse management systems are available on the market, but not all are equipped to handle consignment inventory. Many organizations opt for robust software designed to enhance control over various inventory tasks. Ideally, these solutions should track inventory sent by the supplier to the retailer, signal when restocking is needed to prevent stockouts, and monitor what the supplier must replenish in their own stock. These features assist suppliers in purchasing the right products, reducing excess stock at retail sites, and saving on shipping costs.

The Pros and Cons of Consignment Inventory

For Suppliers:

Pros:

- Enhanced Visibility: Consignment inventory software allows suppliers to reach new audiences through retail stores, generating revenue without the need for retail space or additional staff.

- Testing Opportunities: Suppliers can test new products in different markets, evaluating their performance based on sales.

- Reduced Inventory Costs: Storing large quantities of goods in warehouses can lead to reduced carrying costs by partnering with retail outlets.

Cons:

- Increased Costs: Suppliers must consider expenses like shipping, storage, and potential damages to goods.

- Uncertain Sales Efforts: Dependence on retailers for product promotion can make it challenging to gauge their commitment to selling the goods.

- Unpredictable Cash Flow: Suppliers may experience delays or lower-than-expected payments, as their income depends on retailer sales.

For Retailers:

Pros:

- Low Financial Risk: Retailers pay for products only when sold, avoiding capital loss on unsold inventory and enabling the introduction of new products without financial risk.

- Increased Sales Potential: Consigned goods diversify inventory, potentially boosting sales and profits.

- Reduced Storage Needs: Retailers can restock based on customer demand, avoiding special storage requirements and returning unsold products.

Cons:

- Risk of Damaged Inventory: Holding consigned goods for an extended period increases the risk of damage, and retailers may be responsible for these costs, even if the items don’t sell.

- Management Complexity: Tracking consigned goods can sometimes lead to confusion and errors, prompting businesses to consider purchasing warehouse management solutions.

- Additional Costs: Retailers may need to cover certain expenses until items are sold, such as securing products.

Best Practices for Consignment Inventory

Effectively managing consignment inventory can become a complex task without proper procedures in place. Suppliers and retailers should collaborate to establish a mutually beneficial contract and nurture a strong partnership. They should leverage suitable technology for their inventory requirements, diversify their sales avenues, and prioritize open communication. Here are some recommended practices for consignment inventory management:

- Establish a Robust Contract: The contract serves as the foundation for a successful consignment inventory arrangement. Both the supplier and retailer must have a clear understanding of the agreement’s terms, encompassing responsibilities for shipping, returns, payment timelines, and liability for damaged or lost items. For instance, a retail inventory management contract should specify how inventory counting and management occur, detail deposit or commission requirements, and outline efforts to sell the goods in good faith within a reasonable timeframe.

- Foster a Strong Business Relationship: Cultivating a mutually beneficial relationship with your business partner is of utmost importance. Suppliers should strive for the success of their products, while retailers should exert considerable effort in promoting the supplier’s products. The more both parties collaborate to present the right products to the right customers, the stronger the relationship and higher the sales.

- Utilize Appropriate Technology: Conventional inventory software may not suffice for consignment inventory management. Specialized consignment management systems are needed to track goods and invoices accurately. Organizations should explore solutions that offer data analytics and provide visibility into inventory for both the supplier and retailer, thereby reducing data disparities between the two parties.

- Diversify Sales Channels: Not all partnerships may thrive, making it essential to seek multiple consignment inventory management partners. This approach mitigates risks for both suppliers and retailers by providing alternative business options.

- Maintain Effective Communication: Effective communication between the supplier and retailer is essential throughout the partnership. When issues arise, both parties should actively seek mutually agreeable solutions, reinforcing their commitment to the contract and the strength of their business relationship.

Consignment Inventory Accounting

In the realm of consignment inventory management accounting, both the supplier and the retailer are involved in tracking consignment sales. However, it’s essential to note that consigned goods are part of the supplier’s inventory exclusively. Despite the retailer being responsible for selling these goods, they do not assume ownership. The retailer’s involvement in accounting occurs only at the point of sale, which reflects on the balance sheet. At that juncture, the revenue from the sale and the payment to the supplier are recorded.

Gain Real-Time, Comprehensive Insight into Inventory with PALMS™ Smart WMS

Securing the right technology for effective consignment inventory management is pivotal for the success of such partnerships. Conventional tools may fall short in this regard. Your organization will benefit from a specialized solution, a consignment management system like PALMS™ Smart WMS. It is a warehouse digital transformation tool that offers a unified, real-time inventory view across all locations and sales channels. This consignment inventory software integrates seamlessly throughout the warehouse, offering automated inventory tracking, predefined fulfillment rules to eliminate multiple shipments for a single order, and dynamic management of item-reorder points and preferred stock levels using historical and seasonal data.

FAQs

What is a consignment warehouse?

A consignment warehouse is a storage facility managed by the supplier to store goods, ensuring swift deliveries to retailers.

What is a consignment stock contract?

In a consignment stock agreement, the supplier dispatches a stock of goods to a retailer while retaining ownership until the retailer sells them.

What is consigned inventory?

Consigned inventory from a supplier occurs when one party (e.g., dealer, agent, distributor) holds inventory that remains the property of another party (e.g., manufacturer or primary contractor) based on mutual agreement.

How do you record consigned goods?

Consigned goods should be recorded in warehouse management systems explicitly designed to support it, or consignment inventory software.

Do you include consignment in inventory?

Goods held on consignment are incorporated into the supplier’s inventory, not the retailer’s.

What is an example of consignment inventory management?

A shoe store might collaborate with a small designer to sell some of the designer’s products in-store. In this scenario, the retailer doesn’t need to order the shoes themselves, and the designer manages the consignment stock.